Weighing Solutions for the Pharmaceutical Industry: Ensuring Accuracy and Compliance

The pharmaceutical industry is one of the most highly regulated sectors in the world, with stringent standards in place to ensure the safety and efficacy of drugs and medical products. In this environment, accuracy and compliance are paramount. Weighing equipment plays a crucial role in pharmaceutical processes, and it must meet specific requirements to ensure both accuracy and adherence to regulatory standards, as we will explore further in this blog.

1. Precise Measurements for Formulations

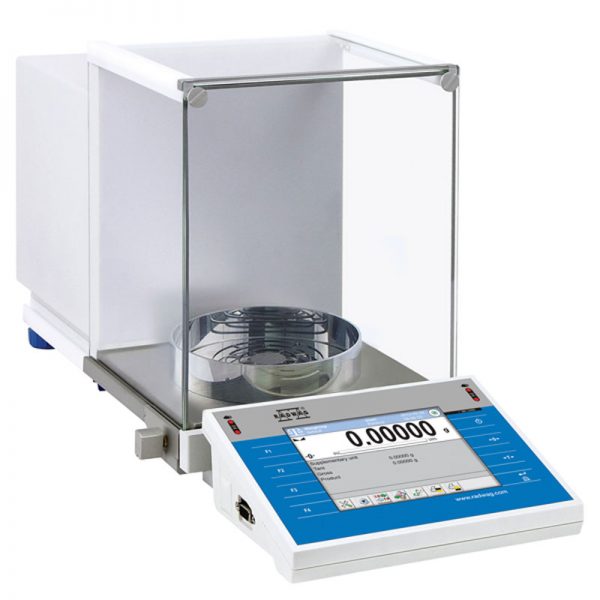

In the pharmaceutical industry, even the smallest variations in ingredient quantities can have a significant impact on the quality and effectiveness of the final product. Lab balances used in pharmaceutical manufacturing must provide precise measurements to ensure that formulations are consistent and meet the required standards.

2. Compliance with Regulatory Standards

Pharmaceutical companies operating in the UK are subject to a range of strict regulatory standards and guidelines, including Good Manufacturing Practice (GMP) as defined by the Medicines and Healthcare Products Regulatory Agency (MHRA). Weighing equipment used in pharmaceutical manufacturing must be designed and calibrated to adhere to these UK-specific standards. This ensures that the final pharmaceutical products not only meet quality and safety criteria but also comply with the rigorous regulations set forth by the MHRA and other relevant UK authorities.

3. Eliminating Cross-Contamination

Pharmaceutical manufacturing facilities handle a wide range of active pharmaceutical ingredients (APIs), many of which are potent and can cause cross-contamination if not handled with care. Weighing equipment used in the pharmaceutical industry should be designed to minimise the risk of cross-contamination and ensure the safety of both products and operators.

4. Data Integrity and Traceability

Data integrity is of paramount importance in pharmaceutical manufacturing. Weighing solutions should incorporate advanced data capture and management systems to ensure traceability and compliance with record-keeping requirements. This not only helps in quality control but also in the event of audits or investigations.

5. Hygiene and Cleanliness

Pharmaceutical manufacturing facilities require a high level of cleanliness and hygiene. Weighing equipment should be easy to clean and maintain to prevent any risk of contamination. The materials used in manufacturing the equipment should also be compatible with the cleaning and sterilisation methods used in pharmaceutical facilities.

6. Customisation for Specific Needs

Each pharmaceutical manufacturing process is unique, and the weighing equipment should be customisable to meet the specific needs of a particular process. Whether it’s high-speed production, quality control, or research and development, the weighing solutions should be able to adapt to that process.

The pharmaceutical industry demands weighing solutions that are not only accurate but also compliant with stringent regulatory standards. Micro Weighing Solutions provides a range of weighing equipment suitable for pharmaceuticals, from microbalances to end of line automatic checkweighers. This equipment is engineered to meet these specific requirements, offering precision, compliance and customisation for the pharmaceutical sector. We also provide a range of ATEX scales designed for use in hazardous areas. With a commitment to quality and innovation, MWS provides the solutions that the pharmaceutical industry can trust.

For more information on our weighing equipment tailored for the pharmaceutical industry, please contact us or explore our products. We look forward to partnering with you to ensure the accuracy and compliance of your pharmaceutical processes.