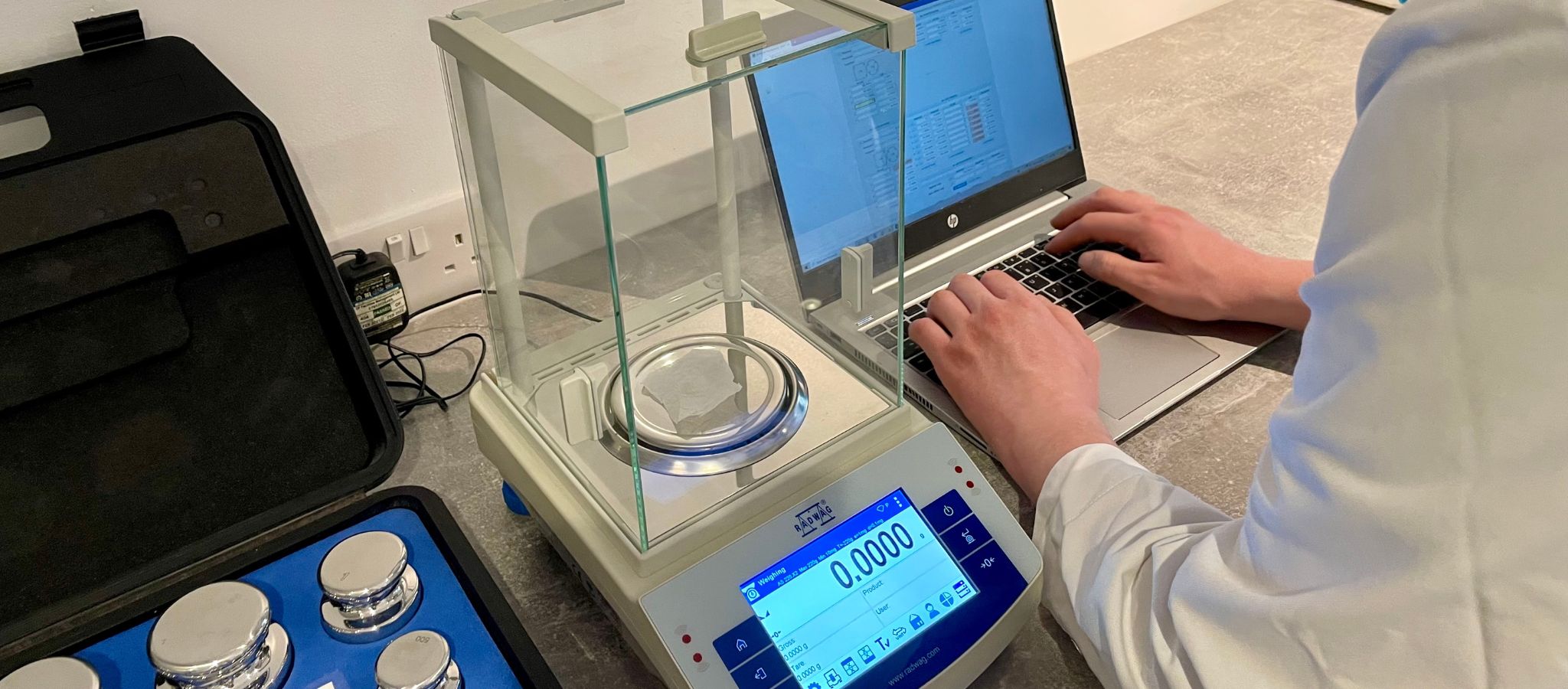

Weighing Errors in the Lab: Causes, Solutions, and Reliable Support

When it comes to weighing in the lab, even seemingly minor errors can propagate, leading to significant inaccuracies and unreliable results. Understanding the common causes of weighing errors and implementing effective solutions is crucial for maintaining data integrity.

Below are some of the more common causes of weighing errors found in the lab, and what you can do about them.

Environmental Factors

- Air Currents: Drafts from open windows, HVAC systems, or even movement within the lab can destabilise the balance reading. To minimise this, place the balance in a dedicated, draft-free area.

- Temperature Fluctuations: Changes in temperature can affect the balance’s internal components and the sample itself, causing drift or instability. Maintain a stable temperature in the lab to reduce this risk.

- Humidity: Similar to temperature, high humidity can lead to moisture absorption by samples or the balance, affecting the measured mass. Ensure the humidity levels remain the same throughout the day.

- Vibrations: External vibrations from nearby equipment or foot traffic can interfere with the balance’s stability. Reduce this issue by utilising anti-vibration tables or platforms.

Balance-Related Issues

- Calibration Errors: An improperly calibrated balance will produce inaccurate readings. Make sure you perform regular calibrations using certified weights, and that you get regular third party calibrations from an accredited service provider.

- Levelling Issues: Balances must be perfectly level to ensure accurate measurements. Ensure the balance is properly levelled before you begin the weighing process.

- Static Electricity: Static buildup can attract dust or cause erratic readings, especially with dry powders. Employ the use of an anti-static device to reduce this risk.

- Contamination: Residue from previous samples can affect the current measurement. Clean the balance regularly to prevent contamination.

- Balance Overload: Exceeding the balance’s capacity can damage the instrument and produce unreliable results. Check the max capacity set by the manufacturer and avoid overloading the balance. You should also regularly check and replace worn parts.

User Errors

- Incorrect Weighing Technique: Not using proper weighing procedures, such as taring correctly or placing samples in the centre of the pan, can lead to errors. Follow the user manual’s instructions on how to use proper weighing techniques, including taring and centring samples.

- Parallax Errors: Reading the display at an angle can cause parallax errors. Ensure you always read the display directly from eye level.

- Sample Handling: Inconsistent sample handling, such as not allowing samples to reach room temperature before weighing, can affect accuracy. Allow samples to reach room temperature before weighing and use appropriate containers and handling tools.

- Transcribing Errors: Incorrectly recording or transcribing the displayed weight will produce inaccurate results. Double-check recorded weights and use calibration weights that have up to date certification.

- Finally, using balances that have a high level of readability, and repeatability is important, and can reduce errors.

Reliable Support from MWS

Maintaining the accuracy of your laboratory balances is crucial for reliable results. MWS not only supplies a wide range of high-quality lab and analytical balances but also provides comprehensive support to ensure optimal performance. Our team of experienced service engineers can troubleshoot problems, perform necessary repairs, and provide both ISO 9001 and UKAS calibrations. By partnering with MWS, you can have confidence in the accuracy and reliability of your weighing processes, minimising errors and maximising the integrity of your lab work. Contact us today to find out more.