Victor Pizza’s Productivity Skyrockets with Flow Wrapper Solution

In a significant boost to productivity and efficiency, Victor Pizza, a renowned name in the UK food service industry, has achieved remarkable operational improvements through the adoption of ULMA Packaging’s cutting-edge Sienna Flow Wrapper.

Known for its high-quality pizza products since the 1970s, Victor Pizza has faced substantial challenges with its previous packaging machinery, which was both unreliable and inefficient, leading to high waste levels and frequent breakdowns.

Furthermore, these issues created bottlenecks that hampered the company’s ability to meet customer expectations and manage waste effectively.

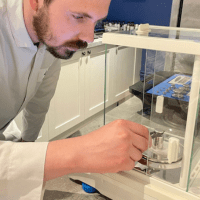

Recognising the need for an upgrade, Victor Pizza turned to its long-standing partner, ULMA Packaging, for a solution that could seamlessly integrate into its expanding operations. Following a visit to ULMA UK’s headquarters, where they observed the capabilities of the latest machinery firsthand, Victor Pizza invested in the Sienna Flow Wrapper.

The bakery manager at Victor Pizza expressed their satisfaction with ULMA’s innovative approach and deep understanding of their needs for scalability and efficiency.

Since the installation of the Sienna Flow Wrapper, Victor Pizza has experienced numerous benefits. Waste production has been reduced by up to 95%, significantly enhancing operational efficiency and sustainability.

Additionally, by reducing the amount of air in each pack, the flow wrapper allows for more pizzas per box, fitting 14 pizzas in a case that previously held 12. This not only maximises space but also delivers substantial savings on boxing and transportation costs. The new packaging is also easier for customers to open, improving the end-user experience.

Victor Pizza’s previous machinery issues were a considerable setback. Frequent breakdowns not only slowed production but also led to increased waste and higher operational costs.

What’s more, the unreliability of the old system was a significant bottleneck, making it difficult for the company to keep up with growing demand and maintain their reputation for timely delivery and high-quality products.

The Sienna Flow Wrapper operates reliably, minimising downtime and increasing throughput. Its user-friendly design has also boosted staff morale, making the production process more enjoyable and efficient.

The bakery manager compared the new system to their old one, describing it as being like night and day and highlighted the team’s excitement about working with such high-performing equipment.

ULMA Packaging UK’s managing director shared their delight in partnering with Victor Pizza once again. They emphasised that Victor Pizza’s commitment to quality and innovation aligns perfectly with ULMA’s values. The success of the Sienna Flow Wrapper at Victor Pizza is a testament to ULMA’s dedication to advancing packaging technology and supporting client growth.

Furthermore, the implementation of the Sienna Flow Wrapper has streamlined Victor Pizza’s logistics. The reduction in air within each pack means fewer trips are needed for transportation, effectively reducing the company’s carbon footprint. This aligns with Victor Pizza’s goal of providing healthier and more sustainable food options.

In conclusion, the collaboration between Victor Pizza and ULMA Packaging has not only addressed the challenges faced by Victor Pizza but has also set a new standard for efficiency and productivity in the industry.

The installation of the Sienna Flow Wrapper marks a significant milestone in Victor Pizza’s journey, positioning them for continued success and innovation in the future. The synergy between the two companies highlights the importance of reliable partnerships and innovative solutions in driving industry advancements.

News Credits: ULMA Packaging flow wrapper solution improves productivity at Victor Pizza

Things you may also like: