Understanding Overhead Weighing Solutions

Overhead weighing solutions, encompassing a range of equipment like crane scales, dynamometers, and integrated solutions, are designed to meet stringent safety regulations, protecting both personnel and equipment. They provide a reliable method for measuring and monitoring loads, contributing to a safer and more productive work environment. This blog looks at the different overhead weighing options available.

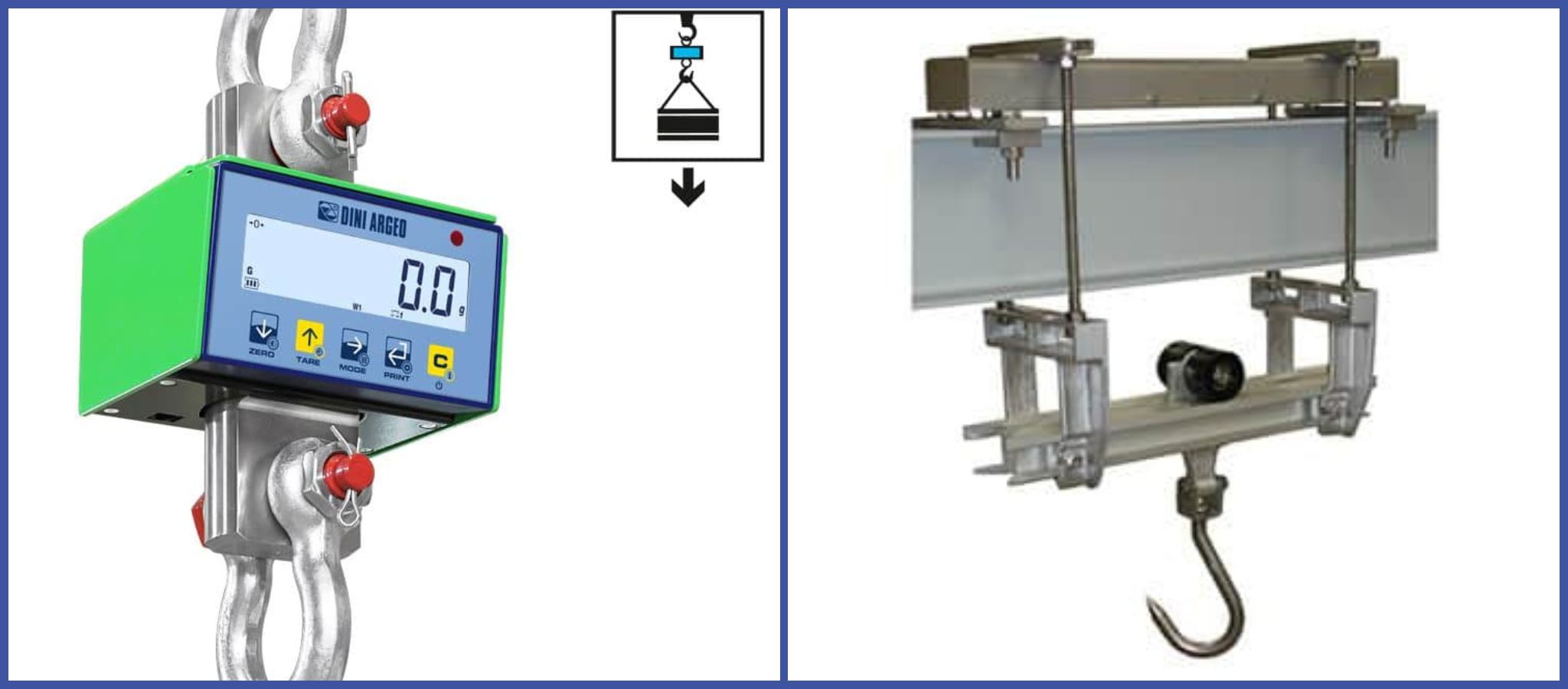

Crane Scales

One of the most common types of overhead weighing solutions is the crane scale. These versatile devices can be adapted for a wide range of lifting capacities, from light-duty tasks within a workshop to heavy-duty operations in demanding environments like shipping yards or metal foundries. Heavy-duty crane scales can even be certified for use in hazardous, explosive atmospheres, demonstrating their adaptability. Crane scales often feature integrated displays for on-the-spot load monitoring, while many models offer wireless communication capabilities, allowing data to be transmitted to remote displays for enhanced visibility and control. This is particularly useful in complex lifting scenarios where operators need real-time feedback from multiple locations.

Integrated Solutions

Beyond crane scales, integrated solutions offer another approach to overhead weighing. These systems seamlessly integrate into existing lifting equipment, transforming cranes, pulleys, and other machinery into precision force measurement tools. This can be achieved through the use of shear web load cells, clevis load pin sensors, or clamp-on load cells, each designed for specific applications. Integrated solutions are particularly valuable when existing infrastructure or industry standards present constraints. They provide a highly accurate and customised approach to load monitoring, often achieving accuracies of 1% or better when calibrated with traceable weights. Regular calibration is essential to maintain this accuracy and ensure the ongoing reliability of the system.

Dynamometers

Dynamometers, sometimes referred to as tension link dynamometers or dyna links, provide another valuable overhead weighing solution. These robust yet lightweight devices are designed for measuring tension forces, whether vertical or horizontal. They find applications in rigging, load testing, crane and elevator certification, and other straight-line lifting scenarios. Like crane scales, dynamometers can often be connected to remote displays via wireless networks, ensuring safe and convenient load monitoring from a distance.

Indicators

The effectiveness of overhead weighing solutions is further enhanced by the use of indicators, remote displays, and wireless network technologies. Indicators provide real-time data and programmable overload warnings, empowering operators with greater control over their lifting operations. Remote displays, including handheld units and wall-mounted scoreboards, can be strategically placed to provide clear visibility of weight data to multiple personnel. Wireless network solutions simplify the connection of crane scales, dynamometers, and other weighing devices to indicators, displays, computers, and printers, creating a seamless flow of information. This connectivity streamlines operations, improves safety, and facilitates data logging and analysis.

Choosing the Right Solution

At MWS, we understand the importance of reliable and accurate overhead weighing solutions. We offer a comprehensive range of equipment designed to meet the diverse needs of our customers. Whatever the application, our team of specialists can help you find the perfect fit. Contact us today for a no-obligation consultation, and let us help you take the weight off your mind.