Client Benefits

- Designed for Improved hygiene levels and ease of sanitation

- Low loading deck for safer use by operators

- Easily replaced non-manufacturer specific parts

- Lower cost of ownership due to longterm lifespan

- Manufactured 100% in the UK using quality stainless steel

- ATEX EU Declaration of Conformity supplied with this model when used with ATEX terminal

| Manufacturer | MWS Ltd (Made in UK) |

| Material | 304 / 316L (option) |

| Capacity | 300kg to 3000kg |

| Sizes | 600 x 600mm to 2000 x 1500mm |

| Finishes | Bead Blast / Electro Polish / Grained |

| Options | ATEX Upgrade / Bespoke Sizes |

| ATEX Rating | Zone 1/2 , 21/22 |

Inquire about "ATEX LPS Stainless Floor Scales"

Additional Info

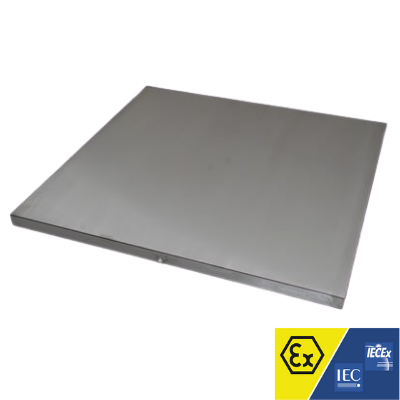

The LPS is a family of platforms that cover a range of stainless steel floor scales for use in food, pharmaceutical and chemical environments, the LPS range is available in a combination of sizes and capacities suitable for a majority of applications.

MWS manufacture these products to order so they can be designed with specific applications in mind, the LPS range have been incorporated into vessels, special models included integrated gutters for chemical run-offs, and scales for use in extreme temperature areas, nuclear waste processing industries, plus many more applications.

The ATEX LPS floor scale is rated to Zone 1/21 and Zone 2/22. The units are supplied with Flintec ATEX / IECEx rated load cells, a stainless steel Intrinsically safe Junction box and Intrinsically safe cable. This model can be supplied with a range of our ATEX weight indicators or load cell amplifiers via Zener Barriers

Construction

The LPS range is manufactured in 304 grade stainless steel (316L available upon request) box section using high end welding techniques. The top loading plate is 5mm thick, ideal for spreading the load and making sure the top does not buckle over time. Fitted with IP68 load cells and junction box as standard guarantying that the LP is waterproof enough for companies with the strictest sanitation policies, the LP is designed for ease of cleaning and can even be washed down with a high pressure / high temperature jet wash.

Finish

A glass bead blast top and bottom is used to finish the LP which gives a high level of hygiene, good enough for a majority of applications, however upon request a grained or electro polish finish can supplied to improve the surface finish further for chemical and pharmaceutical applications.

Options

The LPS can be specified for use in areas where highly corrosive materials maybe present, the upgraded materials included protected cables and 316L stainless steel. Other options include side rails, overload protection and many more options that are client led.

Built to suit

With any platform designed and manufactured by MWS there are a number of options and sizes available as standard, however a USP and key benefit of choosing MWS as a supplier is the ability to manufacture one-offs and systems to suit exact client specifications.

Standard Models

| Model | Size | Height | Capacity | Load Cell |

| LPS60ATEX | 600 x 600 mm | 75 mm | 300 – 600 kg | Flintec SLB |

| LPS75ATEX | 750 x 750 mm | 75 mm | 300 – 600 kg | Flintec SLB |

| LPS80ATEX | 800 x 800 mm | 75 mm | 300 – 600 kg | Flintec SLB |

| LPS1010ATEX | 1000 x 1000 mm | 75 mm | 300 – 1000 kg | Flintec SLB |

| LPS1210ATEX | 1250 x 1000 mm | 75 mm | 300 – 2000 kg | Flintec SLB |

| LPS1212ATEX | 1250 x 1250 mm | 75 mm | 300 – 3000 kg | Flintec SLB |

| LPS1512ATEX | 1500 x 1250 mm | 75 mm | 300 – 3000 kg | Flintec SLB |

| LPS1515ATEX | 1500 x 1500 mm | 75 mm | 300 – 3000 kg | Flintec SLB |

| LPS1812ATEX | 1800 x 1250 mm | 75 mm | 300 – 3000 kg | Flintec SLB |

| LPS2015ATEX | 2000 x 1500 mm | 85 mm | 300 – 3000 kg | Flintec SLB |