Features

- Simple, functional electronics

- Stable, safe mechanics, easily installed on the production line

- Conformity with standards

- Performance and Versatility

- Convenience and simplicity

| Weighing range | up to 1500 g |

| Division | from 0.1 g |

| Accuracy | from ± 0.1 g |

| Throughput | up to 100 ppm |

Inquire about "35D3 Rotational Checkweigher"

PDF Download

Additional Info

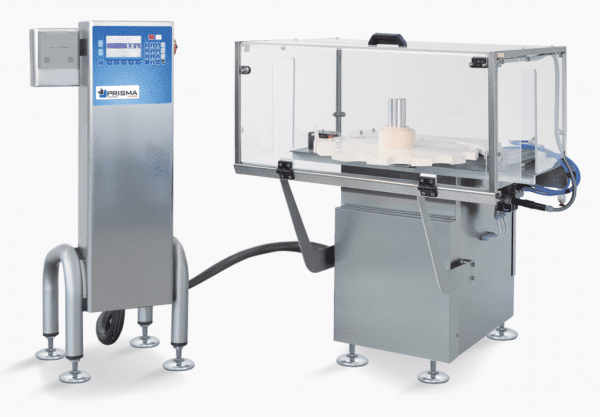

Checkweigher for small and medium sized cylindrical packages.

The 35D3 was designed to run alongside the customer’s line conveyor without interrupting it, reducing installation costs and time to a minimum.

The machine picks the product up directly from the conveyor and, via an alternating feed rotating system, positions and stabilises the product on a static weighing plate, thereby obtaining optimal levels of accuracy and repeatability despite high production speeds. This makes the instrument ideal to check high value, low stability products

Simple, functional electronics

The control panel, connected to the weighing plate by a 3-metre cable, can be easily positioned as is most convenient for the operator, thereby obtaining precious centimetres for the production line. Digital electronics with an alphanumeric display, complete with self-calibration device, mobile average function and 100 storable programs. There are also 2 RS232 C serial ports available. Multi-level password protected access reduces human error to a minimum.

Stable, safe mechanics, easily installed on the production line

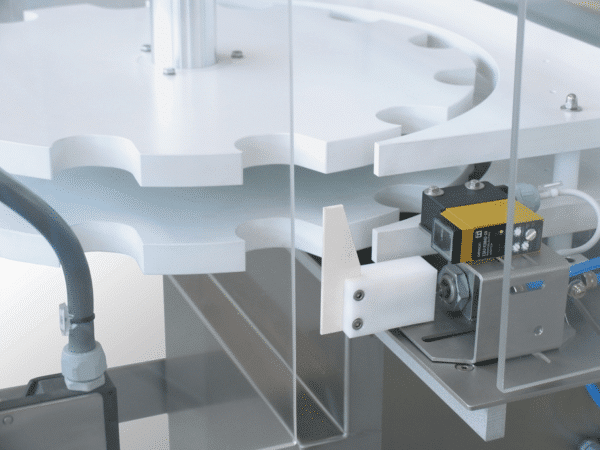

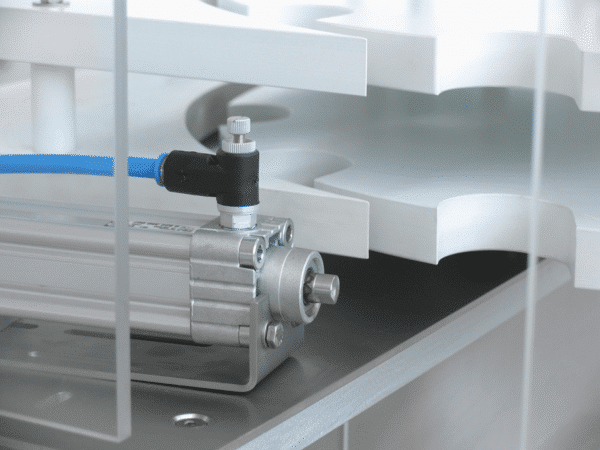

A 12- or 16-pocket star picks up the products from the customer’s belt, transports them onto the weighing plate and realigns them on the customer’s belt, constantly guaranteeing proper handling. The product is weighed when it is completely free, ensuring weighing accuracy. An electro-pneumatic cylinder device installed on the machine regulates the rejection of out-of-tolerance products. The protection on the moving parts of the machine, made of shockproof and accident prevention material, has an IP54 degree of protection. An upper door complete with microswitch allows access to the weighing area.

Experience

30 years of inspection and quality control: an experience that comes to life in every new model that is designed and built in our establishments. The 35D3 made its début in 1986, immediately identified by the market as the ideal machine to check cylindrical, low stability products. Since then, constant perfecting has raised its performance reliability.

Quality

Italian passion for quality is reflected in every machine detail. The attention to every detail, guided by thirty years of experience, is the real added value of PRISMA machines. Finished down to the last detail and made entirely of stainless steel, it is able to withstand intense washing cycles, which can be done extremely quickly.

Conformity with standards

The 35D3 meets the ISO-FDA HACCP standard, the main directives (including, among others: OIML R51 directive, FDA approvals, FAT/SAT IQ/OQ) and complies with customer guidelines and standards (including, among others: BRC and Marks & Spencer).

Performance and Versatility

Our machines meet high levels of performance and product interchangeability; and wherever they are unable to reach, we can design a tailored system for every requirement.

Return on Investment

Imagine how much you can save with a machine that does not waste product, generate false rejects or force production standstills and that protects the brand. Savings that extend over the years, thanks to the high quality of the materials and the longevity of the machine, which are at top market levels. Our sales team knows how to find the solution that best suits any type of budget and expected financial return.

Convenience and simplicity

A simple, streamlined user interface and years of experience installing and integrating into production lines. All the models can be equipped with Ethernet and USB interfaces to transmit data and all the machines can also be connected to a single, centralised data collection system, our Data Manager Tracking.