Powering Your ATEX Weighing Scales: Battery vs. Mains

ATEX Power Sources for Dini Argeo ATEX Indicators

If you are looking to purchase an ATEX rated scale, you may have the option of purchasing either a mains power source or battery. Based on which zone you operate in and the type of indicator, we have the following options available from Dini Argeo.

ZONE 1:

DFWIECEX* – powered with power supply IECEXPW / IECEXPW24 or battery IECEXB

IECEXPW/IECEXPW24 |

IECEXB |

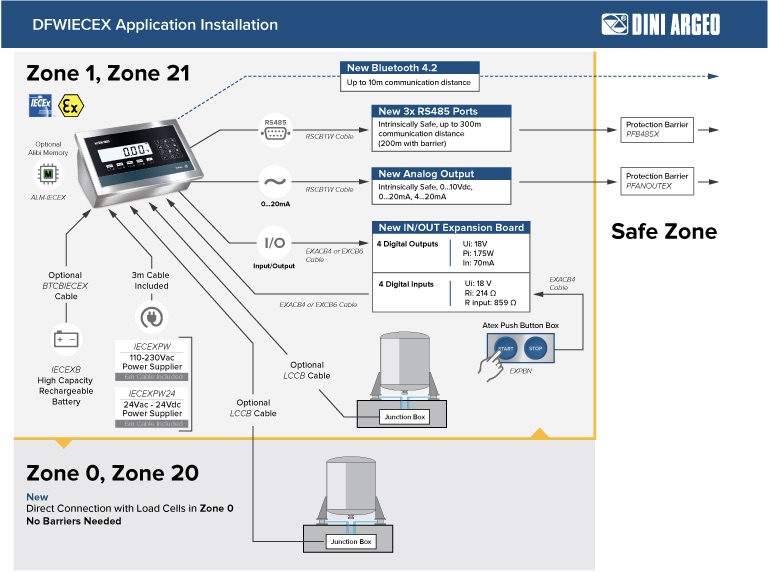

Below is an application installation example for the DFWIECEX:

DFWATEX2GD* – powered with power supply PW200XRDxxx or battery DFWBP76ATEXD

PW200XRDxxx |

DFWBP76ATEXD |

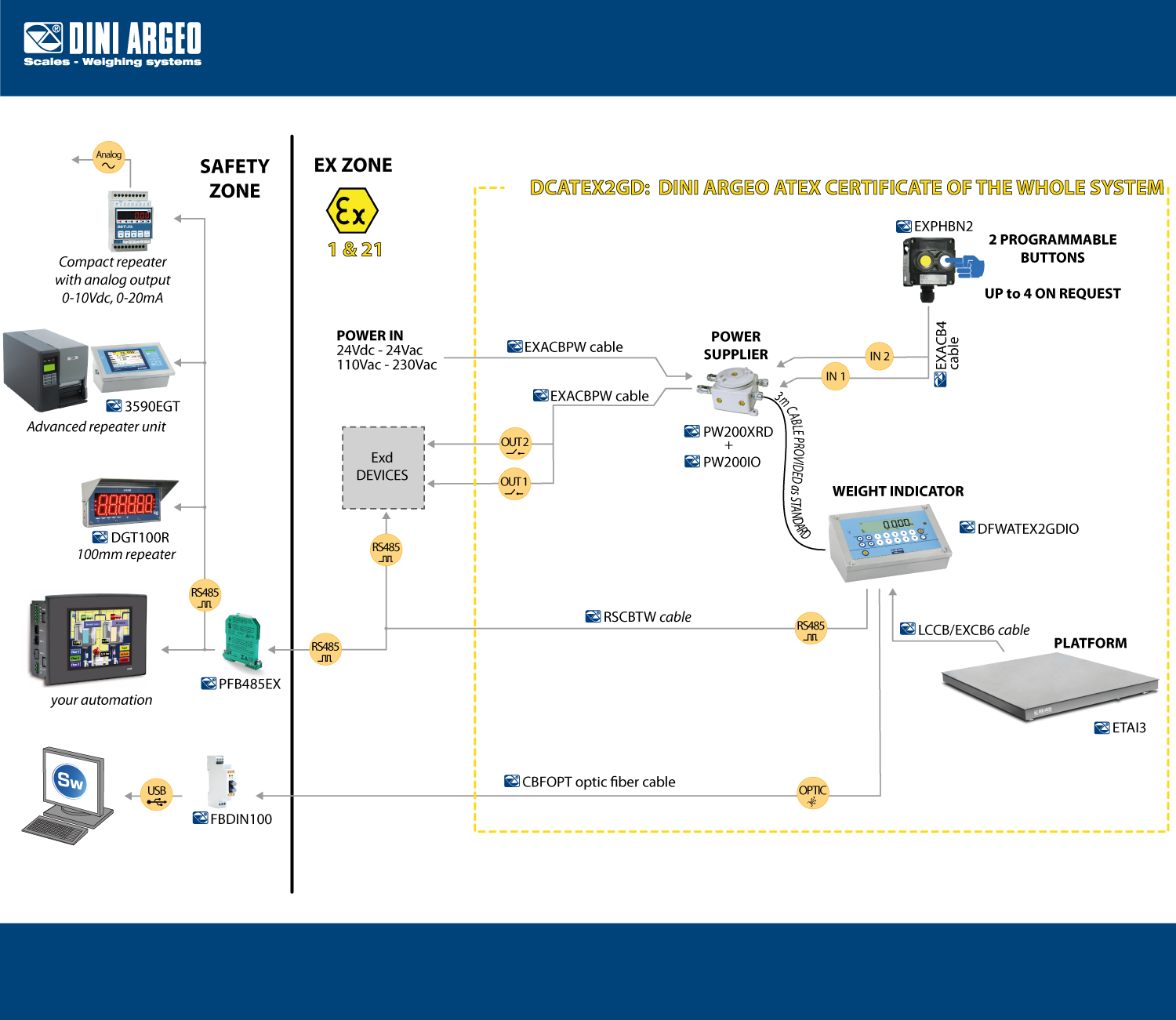

Below is an application installation example for the DFWATEX2GD:

ZONE 2:

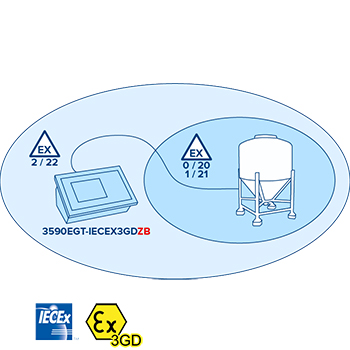

DFWATEX3GD* / 3590EGTC3GD / 3590EGT-IECEX3GD* / DFW-IECEX3GD* / DGT60*3GD

These models all come with an internal power supply. The enclosure of the indicator protects the power source from explosive atmospheres.

Some of these indicators can also be powered by the BP6ESTATEX3GD external battery.

Below is an application installation example for the 3590EGT-IECEX3GD:

|

|

How to Choose the Right Option

Choosing the right power source for your ATEX-certified weighing scales is crucial for both safety and operational efficiency. Whether you opt for battery power or a mains connection, several factors need careful consideration. This guide will walk you through the key aspects to help you make the best decision for your specific needs.

Considerations for Choosing a Power Supply

Before diving into the pros and cons, let’s look at the critical factors influencing your choice:

- Location and Mobility: Where will the scale be used? If it needs to be moved frequently or used in areas without easy access to mains power, battery power is the obvious choice. Static installations often benefit from a mains connection.

- Duty Cycle: How often will the scale be used? For continuous, high-volume weighing, mains power is generally more reliable. Battery life is a limiting factor for frequent use.

- Safety Requirements: ATEX environments demand rigorous safety standards. Ensure both the scale and its power supply are certified for the specific hazardous zone. Consider the potential for sparks or other ignition sources related to power supply connections.

- Maintenance: Batteries require periodic replacement, adding to maintenance costs and downtime. Mains power eliminates this, but the cabling and connections must be regularly inspected for damage in hazardous environments.

- Cost: The initial cost of the scale and power supply is important, but factor in long-term costs like battery replacements or specialised cabling for hazardous areas.

- Environmental Conditions: Extreme temperatures, humidity, or dust can impact the performance and lifespan of both batteries and mains connections. Choose a power supply rated for your specific environment.

Essential Components

In addition to the type of power source you decide to use, you’ll also need to ensure you have the correct components for that type of power source.

Battery-Powered Scales:

- Batteries: The power source for the scale. Must be appropriately certified for the ATEX zone.

- Charger: Used to recharge the batteries. Ensure it is located outside the hazardous area.

Mains-Powered Scales:

- Cable: Connects the scale to the mains power supply. Must be rated for the appropriate voltage, current, and environmental conditions, and be certified for use in hazardous areas. Armoured or shielded cables might be required for added protection.

- Plug/Connector: Must be compatible with the power outlet and certified for use in the ATEX zone. Intrinsically safe connections are often required.

- Power Supply Unit (PSU) or Zener Barrier: Converts the mains voltage to the voltage required by the scale. If separate, it needs to be appropriately certified for hazardous environments. Sometimes the PSU is located outside the hazardous area.

Making the Right Choice

The best power supply option depends entirely on your specific application. If portability and flexibility are paramount, battery power is the way to go. For continuous, reliable operation in a fixed location, mains power is usually preferred.

Remember: Always consult with a qualified professional to ensure your chosen power supply and all associated components are suitable and certified for the specific ATEX zone where the weighing scale will be used. Don’t compromise on safety – it’s the most critical factor in hazardous environments.

Contact us today to consult with one of our ATEX specialists.